High Speed Injection Molding Plastic Syringe Injection Molding Servo

High Speed Injection Moulding MachineHigh Precison Injection Molding

High-speed injection molding machines are designed to significantly reduce cycle times compared to traditional machines. They optimize the injection, cooling, and ejection processes,.

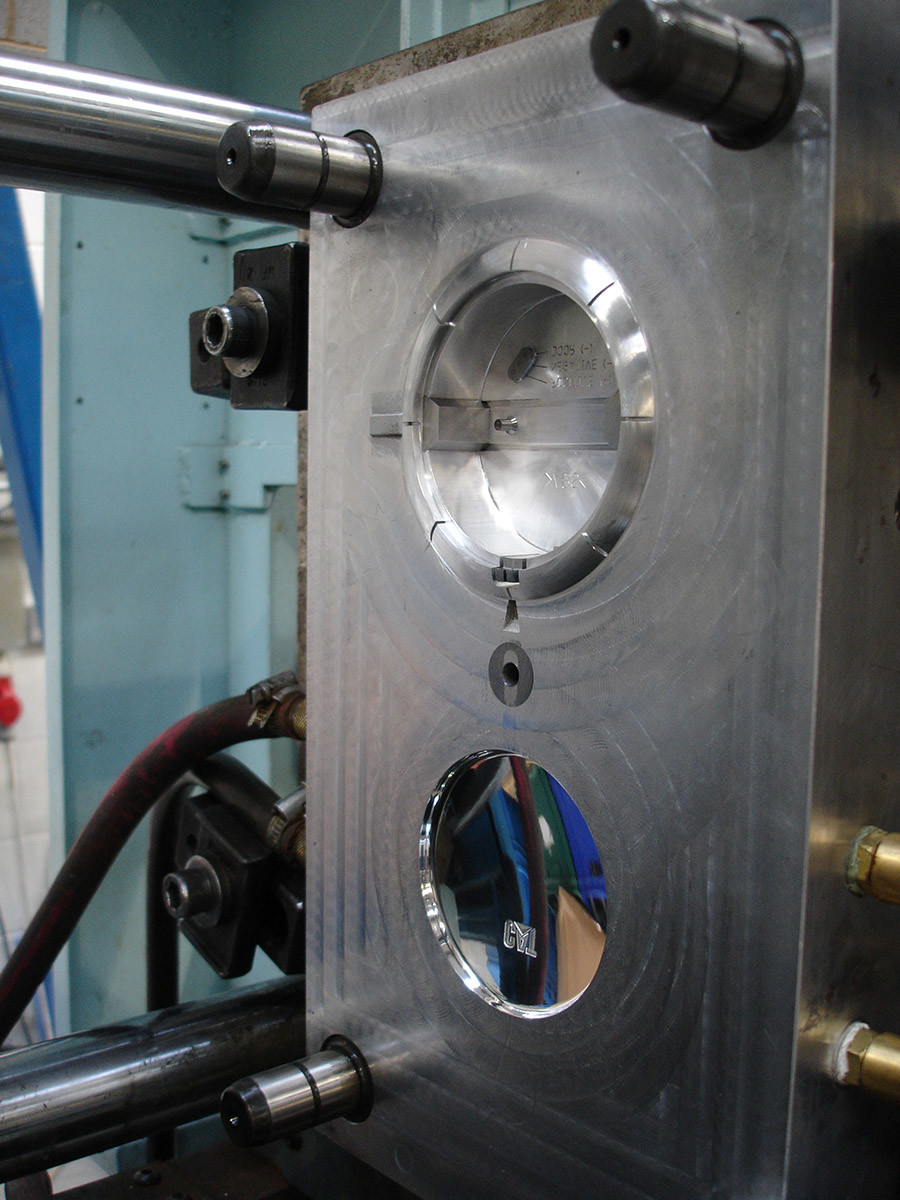

High speed injection mould tools rapitypes

In injection molding, material is fed through a hopper into an extruder, where a reciprocating screw mixes and melts the material then injects it into a mold.. weld quality via advanced control features and gain insights into optimizing your assemblies for welding in these high-performing machines. Join Dukane to unlock the potential of.

Sm22000 2200 Tons of High Quality Automatic Plastic Injection Molding

We offer the most advanced injection compression system in the industry: High speed / high response injection compression control. Maintains tight dynamic parallelism. Accurate alignment of mold open-close. Sodick HSP high speed/high pressre injection molding machine is ideal for high speed injection in under 59"/sec at 50,000 psi.

Pin on Micro injection molding

Available in model sizes from 169 to 1124 U.S. tons, the El-Exis SP has been designed for high-speed production of applications such as thin-wall food packaging, closures for beverages, cartridges, plant pots and buckets. Taking a "best of both worlds" approach to injection molding, the hybrid series combines speed and performance with:

High Speed Injection Moulding MachineHigh Precison Injection Molding

Sumitomo Demag's platform of all-electric injection molding machines spans from 8 to 936 US tons, including micro to mid-sized, high-speed thin-wall/packaging, high-duty, vertical, insert and 2-shot machine series.

High Speed Injection Molding Plastic Syringe Injection Molding Servo

PAC-K3 Series High-speed Injection Molding Machine In response to the evolving landscape of thin-wall containers and heightened production efficiency, the PAC-K3 series emerges as the optimal choice for crafting multi-cavity, thin-wall packaging items. Characterized by its robust rigidity, swift injection pace, and impeccable precision, it.

Low Price High Speed Injection Moulding Machine Manufacturers in China

The injection capacity above 600mm/sec (or 800mm/sec) is called an ultra-high-speed injection machine. The ultra-high-speed injection molding machine is generally used for thin parts molding. The so-called definition of thin-walled products generally means that the finished product with an L/T ratio of 150 or more, or a wall thickness of 1.0~0.

Bigger tie bar space high speed injection moulding machinery for Nylon

1. Filling Time and Material Distribution: Injection speed directly affects the filling time of the mold cavity. A well-adjusted injection speed ensures uniform material distribution and minimizes the risk of short shots or poor surface finish. 2. Weld Line Formation: Weld lines occur when two or more melt fronts meet during the filling process.

350ton high speed injection moulding machine Injection moulding

Our high speed injection molding machine is dedicated design for the thin-wall product with Low-temperature Plasticizing System, Eco-friendly and Energy-saving, Lower Hydraulic System Pressure, Shorter System Response Speed, Faster Injection / Shot Speed, Lower Molecular Internal Stress, Higher Tenacity & toughness Products.

High Speed Injection Moulding MachineHigh Precison Injection Molding

https://www.sumitomo-shi-demag.eu The injection molding machine manufacturer Sumitomo (SHI) Demag Shows high-speed injection molding. The injection molding m.

650ton High Speed Injection Moulding Machine

Sumitomo (SHI) Demag provides an unmatched range of injection molding machinery solutions to meet the needs of high-speed packaging, caps and closures, buckets, containers and other thin-wall product applications.

High Speed Injection Moulding Machine at Rs 155000 Injection Moulding

DKM Fast Speed Injection Molding Machine (200Ton - 1300Ton) The DKM Fast Speed Molding Machine series, ranging from 200 tons to 1300 tons, offers a range of outstanding features that set them apart in the industry. These machines are designed to deliver exceptional performance, precision, and reliability, ensuring optimal results for your.

Large High Speed Injection Moulding Machine Silicone Seal Ring Sealing Plug

High-speed servo injection molding machine for thin-wall products Know More HAIDA HDK Series High-speed injection Molding machine from 2600kN - 4200kN Know More HAIDA HDK Series High-speed injection machine HDK Series High-speed Injection Molding Machine from 260Ton to 420Ton Superior Energy Efficiency

High Speed Thinwall Injection Molding Machine

Advantages of High Injection Speeds. Efficiency in Time: Using a faster injection rate reduces the overall molding cycle, making the production process more efficient. Enhanced Flow: A rapid injection velocity improves the flow of the plastic, which is especially beneficial for the molding of thin-walled components.

high speed injection molding machine,high speed injection molding

The high-speed injection molding machine is efficient, and adopts three-axis linkage, which is commonly referd to as three-circuit. The molding process is: mold clamping - injection - cooling - mold opening (synchronous mold support, material storage) - gap time.

High Speed Injection Moulding / Requirements for highspeed injection

High-Speed, Thin-Wall Molding Doesn't Need an Accumulator | Plastics Technology Published 8/1/2001 High-Speed, Thin-Wall Molding Doesn't Need an Accumulator Forget about using a gas accumulator or a special beefed-up machine to fill thin-wall parts fast. Just let the melt do all the work! Matthew Naitove Contributing Editor, Plastics Technology