Total Productive Maintenance (TPM) Toolshero

An Overview Of The Eight Pillars Of Total Productive Maintenance Vrogue

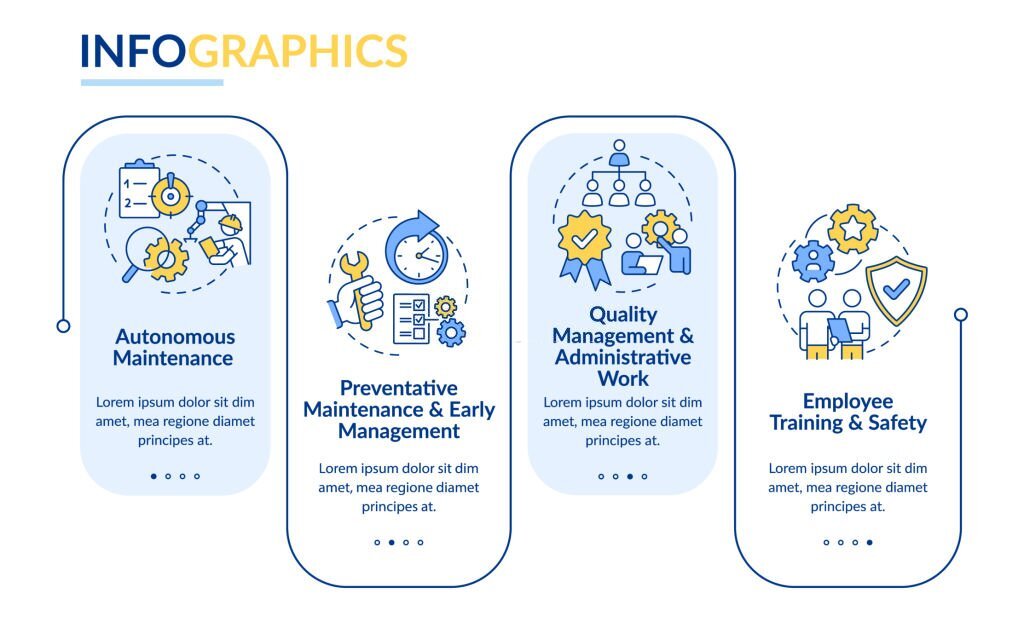

Total Productive Maintenance (TPM) is a comprehensive maintenance approach that involves all employees, from top management to front-line operators, in maintaining equipment to ensure smooth and efficient operations. The primary objective of TPM is to achieve zero breakdowns, zero defects, and zero accidents in manufacturing processes.

Makalah Total Productive Maintenance BELAJAR BIKIN MAKALAH

Makalah Total Productive Maintenance. Uploaded by: Rizky Adi Saputro. October 2019. PDF. Bookmark. Download. This document was uploaded by user and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this DMCA report form. Report DMCA.

Makalah Total Productive Maintenance BELAJAR BIKIN MAKALAH

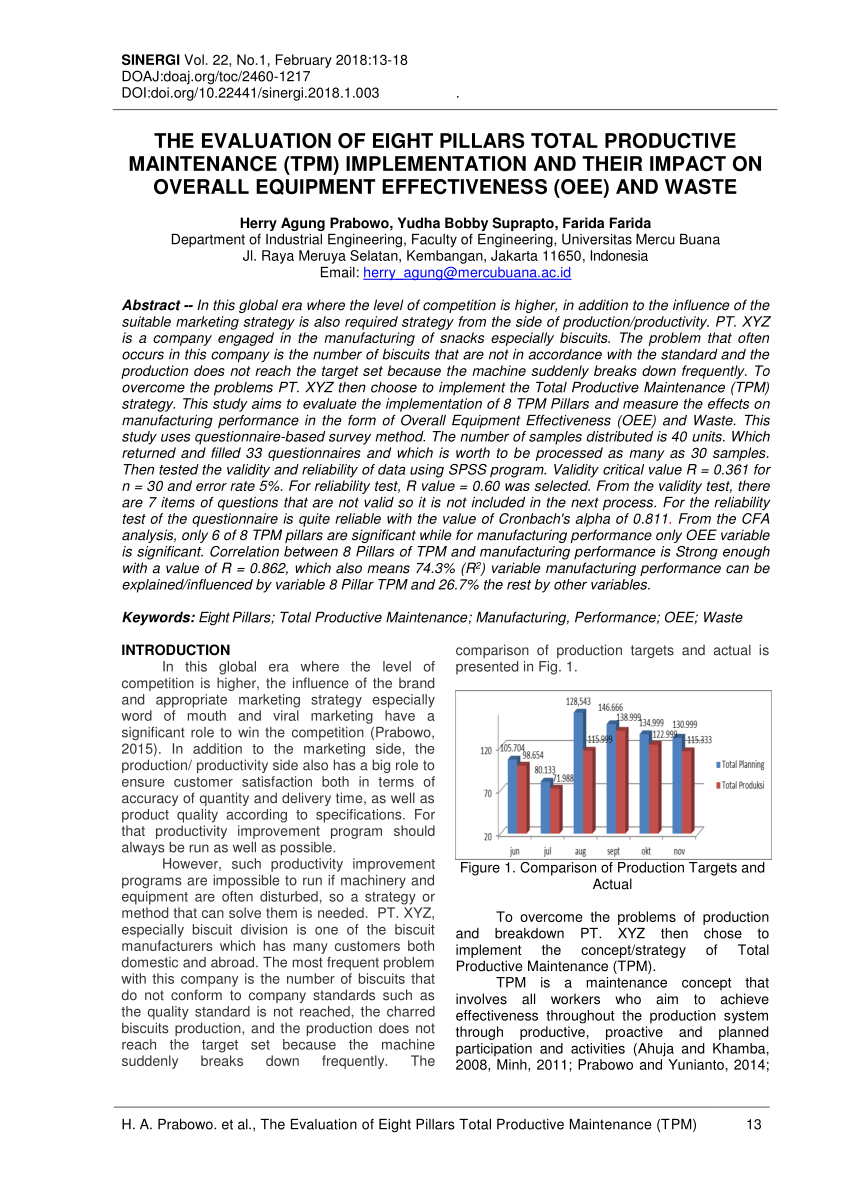

This article aimed to analyze the application of Total Productive Maintenance (TPM) at one of the biggest sugar refinery companies in Indonesia, which encounters decline in productivity within these 4 years. Total Productive Maintenance (TPM) is a system for improving the factory productivity. The implementation of TPM pillars was evaluated through overall equipment effectiveness (OEE), visual.

Makalah Total Quality Manajemen Jefri Dimas Firmansyah MAKALAH TOTAL

Overview. Total Productive Maintenance is a "holistic approach to equipment maintenance that strives to achieve perfect production" (Lean Production, 2021). TPM does this by preventing breakdown, eliminating elements that slow down the process, and perfects production so defects and accidents do not occur. TPM promotes operational.

Total Productive Maintenance How To Achieve Perfect Production

TPM - History: TPM is an innovative Japanese concept. The origin of TPM can be traced back to 1951 when preventive maintenance was introduced in Japan. However the concept of preventive maintenance was taken from USA. Nippondenso was the first company to introduce plant wide preventive maintenance in 1960.

(DOC) Makalah Total Psycal Response Sitti Kurniawanti Basir

OEE (Overall Equipment Effectiveness) is a metric that identifies the percentage of planned production time that is truly productive. It was developed to support TPM initiatives by accurately tracking progress towards achieving "perfect production". An OEE score of 100% is perfect production.

TRAINING ONLINE TOTAL PRODUCTIVE MAINTENANCE

Tujuan penelitian ini, yaitu mengidentifikasi penerapan Total Productive Maintenance di PT Xacti Indonesia, menghitung kinerja produksi dengan menggunakan Overall Equipment Effectiveness (OEE.

Total Productive Maintenance

• Total: means consideration of every aspect and involvement of all employees. • Productive: emphasis on performing activities during production, minimizing pro-duction problems. • Maintenance: independent maintenance of equipment by production operators. There are many definitions of TPM in the literature [1,12,24-29], and each emphasizes

Makalah Total Productive Maintenance BELAJAR BIKIN MAKALAH

Total productive maintenance (TPM) is a high-level maintenance philosophy that has spawned much research and analysis from academics. Instead of doing a deep dive into all the tools, techniques, and methodologies involved in TPM, our goal is to introduce the main ideas of total productive maintenance in a simple, straightforward way.

(DOC) makalah Total Hip Replacement chindy wulan Academia.edu

PT. KPS is one steel company in Indonesia that produces steel products in the form of slab and plate that is marketed in the country up to foreign countries. Cold leveller machine is a machine that serves to flatten the surface of the plate. Problems occurred in the machinery that is often experienced a breakdown so that the plate with uneven surfaces more and more because of the time machine.

Metode za organizacijo VITKE ali LEAN proizvodnje DemetraDemetra

4. Huda,R.B, 2019, Analisa Total Productive Maintenance dengan Metode Overall Equipment Effectiveness pada Mesin Unigrator di PG Semboro, Skripsi. Jember: UniversitasJember.. Template Makalah. ISSN: 2962-5300 (Online) 2088-060X (Print) Information. For Readers For Authors

Makalah Total Productive Maintenance BELAJAR BIKIN MAKALAH

Definition of TPM. Total Productive Maintenance is an innovative approach to equipment maintenance involving maintenance personnel and operators working in teams focusing on eliminating equipment breakdowns and equipment related defects. TPM means equipment is well maintained, eliminating any chance of failures.

TOTAL PRODUCTIVE MAINTENANCE (TPM) Informasi Training Center

maintenance. The aim of productive maintenance was to maximize plant and equipment effectiveness to achieve optimum life cycle cost of production equipment. By then Nippon Denso had made quality circles, involving the employees participation. Thus all employees took part in implementing Productive maintenance. Based on these developments

APA ITU TPM (TOTAL PRODUCTIVE MAINTENANCE)

LANDASAN TEORI 2.1 Total Productive Maintenance / Sistem Perawatan Terpadu. Channel 3.0. Manajemen pemeliharaan mesin atau peralatan sudah dimulai dengan lebih dikenal Preventive Maintenance (pemeliharaan pencegahan) yang kemudian berkembang menjadi Productive Maintenance. Kedua metode pemeliharaan ini umumnya disingkat dengan PM dan pertama.

Makalah Total Productive Maintenance BELAJAR BIKIN MAKALAH

Makalah ini membahas sebagian. Total Productive Maintenance is an effective program and is a new concept established in the equipment maintenance plan (Sethia et al., 2016). TPM approach allows the manufacturing system to change for the better and has an impact on the company's

Total Productive Maintenance BEXPERT INDOPRIMA

View. Show abstract.. Total productive maintenance (TPM)is a lean manufacturing philosophy with the aim of achieving high quality and productivity by eliminating machine breakdowns, small stops.